Technical advancements and operational efficiency – Innovations in brick slip cladding

Stofix Group Technical Director Andy McKechnie explains how in 2024, the business has made significant strides in both technical advancements and operational efficiency.

Tell us about the unique design and scheduling service provided by Stofix?

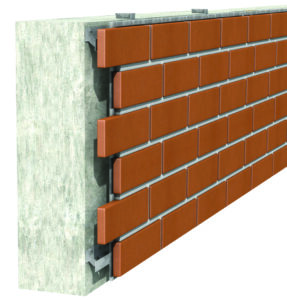

“Stofix remains the only company in our field that fully designs and schedules our brick slip facade product, offering bespoke solutions with our unique panelised system. We have an in-house team of over 15 designers and we take on all design responsibility ensuring our system is designed and detailed to our client’s exact specification. Unlike other systems which rely on time-intensive, on-site modifications, our pre-pointed panels significantly reduce installation time and complexity. Additionally, our lightweight brick slip system is just 37 kg per square metre, requiring less structural support and simplifying the overall build process.

How has operational efficiency and innovation impacted Stofix’s growth?

The operational efficiencies and innovations we’ve implemented in the last 12 months have significantly contributed to our growth, with Stofix Group’s factory output increasing by 20% in 2023/2024. This growth is especially evident in the UK market, where we’ve seen an impressive 30% increase—from 36k m² in 2023 to 52k m² in 2024. These numbers are a testament to how operational efficiency and innovation can drive substantial growth in both production and market reach.

How does Stofix ensure efficiency, waste reduction and quality control?

We’ve revolutionised our production process with the completion of our bespoke CAD system, CADflow. This innovative system automates product scheduling, reducing errors by 97% and cutting waste by 65%. What was once a manual process is now streamlined and highly efficient, allowing us to maintain superior quality control.

Tell us about Stofix fire testing accreditation?

One of our key achievements was the successful renewal of our fire testing accreditation (BS 13501) in 2024. Our product has been rigorously tested from both the front and rear, earning an A2, S1, d0 rating. While renewal is expected, it’s noteworthy that testing from both sides isn’t always done in our industry, underscoring our commitment to safety and quality.

What external factors have affected the company this year?

A significant portion of our UK market is in the public sector (i.e. The Department for Education’s (DfE) School Rebuilding Programme), which was heavily impacted by the uncertainty surrounding the UK election process. This caused considerable project slippage, presenting a major challenge for us. To overcome this, we had to be highly flexible, shifting our focus to pipeline projects that could be advanced to cover the delays. This approach allowed us to maintain momentum despite the disruptions. Looking forward, the future is promising as the Labour government is expected to increase public spending, strengthen the economy, and drive the development of more high-rise apartment blocks.

Department for Education ten year re-build programme, Thames Park School installed by Caxton Facades.

What are your goals and aspirations for Stofix in the next twelve months and beyond?

We’ve expanded our technical services department to provide enhanced support to our global partners. Later this year we’ll be launching the Stofix Technical Services Centre, led by Head of Technical, Richard Bell to further strengthen our partner relationships by offering increased technical assistance and expertise.

Tell us about your growth strategy for the next 12 months?

Our goals for the next twelve months focus on sustainable growth. We aim to expand the UK market to 60-65k m² while strategically entering more European markets at a pace. This expansion will necessitate increased capacity at our factory to meet the growing demand. Our overarching plan is to ensure healthy, sustainable growth over the coming years, with our product now available across Europe. By continuing to innovate and maintain operational excellence, we are confident in our ability to drive further growth and success for Stofix Group.

How has your role and your team developed in the last 12 months?

I became a statutory director of Stofix Poland and have had legal responsibility for factory operations since July 2023. I also sit on the board of Stofix OY (Stofix Group). Gaining control of the factory has allowed us to increase efficiency which in turn allows us to make more product with consistent high quality and ensure our prices are competitive. I have installed a support network for the factory including Group Operations Director, Alex Porter, and Plant Manager Karol Bzdawka.

We are also fortunate to have a base management structure at the factory which includes many talented, loyal team members, many of whom have worked at the factory for many years. I am supported and led by Stofix Group Board Chairman Michael Hardy and Stofix Group Managing Director Krister Sigfrids.The future is bright as the demand for Stofix continues on a rapid growth trajectory”.

Read more about our DofE projects Thames Park, Bowbrook School, Woodbridge Road, and West Coventry Academy. Read more from Stofix specialist installer, Caxton Facades.